5 Control Layer Implementation

The Control Layer forms the decision-making core of RobotZero, managing the robot’s behaviour in response to sensor inputs and track conditions. This layer translates raw sensor data into actionable controls, implementing the robot’s core line-following logic while managing special track features like markers and intersections. Operating between the Hardware Interface Layer and the Main Control system, it ensures smooth and predictable robot behaviour under varying conditions.

TODO: This version of CourseMarkers has not been run yet. At this stage of development (Dec/2024), this code is purely theoretical and REQUIRES EXTENSIVE TESTING. This implementation represents our current design approach but has not been validated in real-world conditions.

The CourseMarkers class represents the primary control component, implementing track feature detection and corresponding behaviour adjustments. This class processes marker sensor data to identify track features and manages the robot’s response to these features, including speed changes, lap counting, and precision mode transitions. Through its state machine implementation, it ensures reliable detection of track features and smooth transitions between different operating modes.

The ProfileManager class complements the control system by managing operation profiles and parameters based on the current debug level. When DEBUG_LEVEL is greater than 0, it provides different speed and control parameter sets optimized for either analysis (DEBUG_LEVEL = 1) or high-speed performance (DEBUG_LEVEL = 2). This class enables the robot to maintain consistent control logic while operating under different performance requirements, making it an essential component for both development and competition scenarios.

6 CourseMarkers Implementation

The CourseMarkers class represents a control component implementing track feature detection and robot behaviour management through an optimized state-based approach. This implementation focuses on efficient timing control, reliable marker detection, and seamless integration with both the debug system and main control loop.

6.1 Core Architecture

class CourseMarkers {

private:

// Timing control

static uint32_t lastReadTime;

static const uint16_t MARKER_READ_INTERVAL = 2; // 2ms read interval

// State tracking

static int speed;

static int lastMarkerState;

static int previousMarkerState;

static int oldMarkerState;

static int currentMarkerState;

static int16_t leftMarkerDetected;

static int16_t rightMarkerDetected;

// Motion control

static bool isTurning;

static bool isExitingTurn;

static uint8_t boostCountdown;

// Timing control

static Timer stopTimer;

static Timer slowdownTimer;

};The implementation utilizes a set of static members to maintain system state while minimizing memory usage. Key innovations include:

Time-Controlled Operation: The system implements a precise timing mechanism that regulates marker reading frequency:

void readCourseMarkers() { uint32_t currentTime = millis(); if (currentTime - lastReadTime < MARKER_READ_INTERVAL) { return; } lastReadTime = currentTime; // Optimized marker reading bool leftDetected = analogRead(PIN_MARKER_LEFT) <= MARKER_DETECTION_THRESHOLD; bool rightDetected = analogRead(PIN_MARKER_RIGHT) <= MARKER_DETECTION_THRESHOLD; currentMarkerState = (leftDetected << 1) | rightDetected; digitalWrite(PIN_STATUS_LED, leftDetected || rightDetected); }This time-controlled approach ensures consistent sampling intervals while preventing unnecessary processor load. The 2ms interval was chosen based on empirical testing to balance between reliable detection and system performance.

State Machine Implementation: The system maintains a three-level state history (current, previous, and old) enabling pattern recognition:

switch (currentMarkerState) { case 0: // No markers if (lastMarkerState == 2 && previousMarkerState == 0) { handleFinishLine(); } else if (lastMarkerState == 1 && previousMarkerState == 0) { handleSpeedMode(); } else if (lastMarkerState == 3 || previousMarkerState == 3 || oldMarkerState == 3) { handleIntersection(); } break; }

The state machine processes four distinct states: - State 0: No markers detected; - State 1: Left marker only; - State 2: Right marker only; - State 3: Both markers detected.

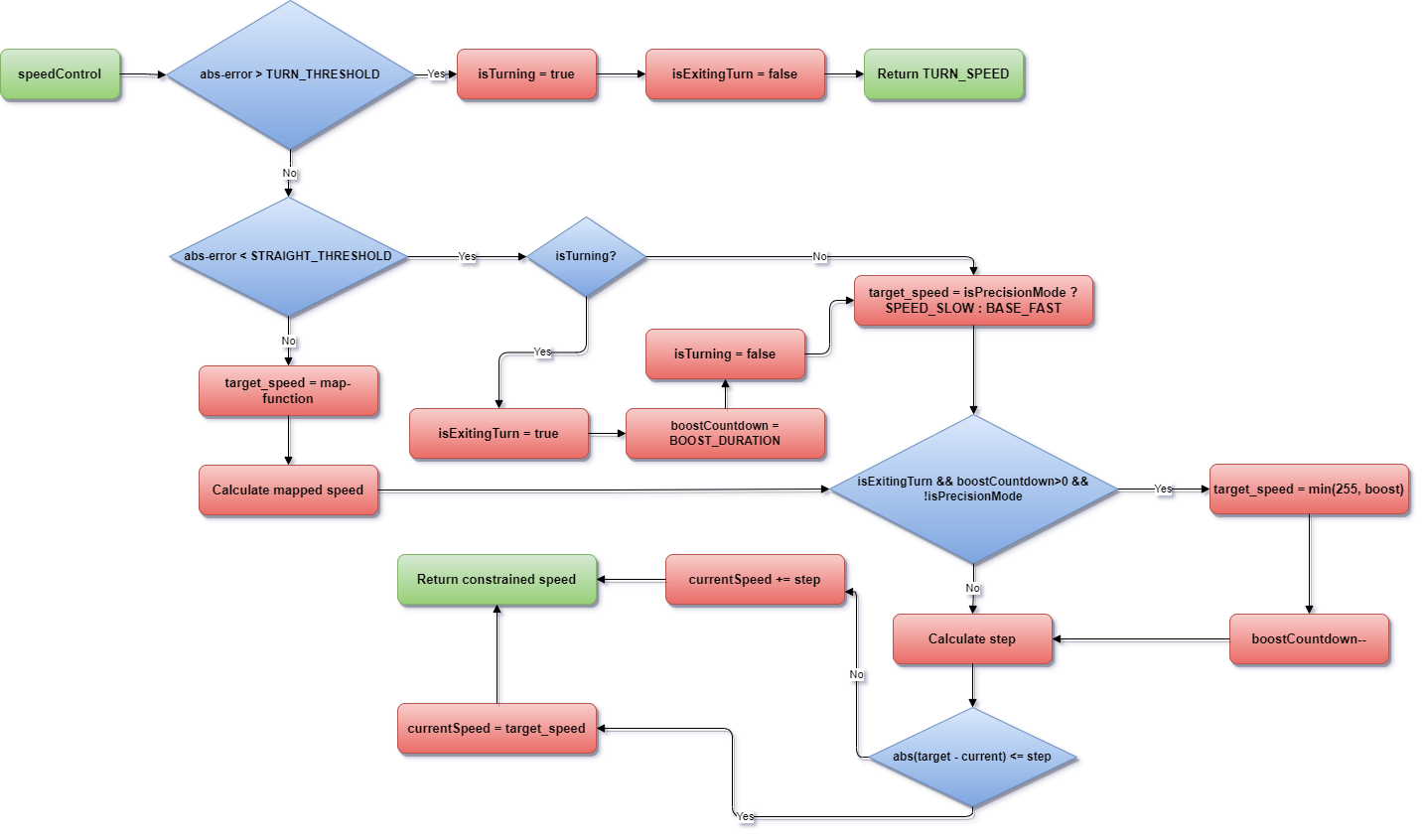

Speed Control System: Implements an optimized decision tree for rapid response:

int CourseMarkers::speedControl(int error) { // Early curve detection bool curve_detected = abs(error) > TURN_THRESHOLD; if (curve_detected) { isTurning = true; isExitingTurn = false; return TURN_SPEED; } bool straight_detected = abs(error) < STRAIGHT_THRESHOLD; int target_speed; if (straight_detected) { if (isTurning) { isExitingTurn = true; boostCountdown = BOOST_DURATION; } isTurning = false; target_speed = isPrecisionMode ? SPEED_SLOW : BASE_FAST; } else { target_speed = map(abs(error), STRAIGHT_THRESHOLD, TURN_THRESHOLD, (isPrecisionMode ? SPEED_SLOW : BASE_FAST), TURN_SPEED); } // Boost control if (isExitingTurn && boostCountdown > 0 && !isPrecisionMode) { target_speed = min(255, target_speed + BOOST_INCREMENT); boostCountdown--; } // Speed adjustment int step = (target_speed > currentSpeed) ? ACCELERATION_STEP : BRAKE_STEP; if (abs(target_speed - currentSpeed) <= step) { currentSpeed = target_speed; } else { currentSpeed += (target_speed > currentSpeed) ? step : -step; } return constrain(currentSpeed, TURN_SPEED, (isPrecisionMode ? SPEED_SLOW : BASE_FAST)); }Debug Integration: When

DEBUG_LEVEL > 0, the system integrates with the logging framework:void handleFinishLine() { lapCount++; if (lapCount == 2 && !isStopSequenceActive) { isStopSequenceActive = true; slowdownTimer.Start(50); stopTimer.Start(STOP_DELAY); #if DEBUG_LEVEL > 0 FlashManager::setLogReady(); #endif } }Event Handling: The system implements specialized handlers for different track features:

handleFinishLine(): Manages lap counting and stop sequence;handleSpeedMode(): Controls precision/speed mode transitions;handleIntersection(): Logs intersection detection.

6.1.1 State Management

The state management system operates through a decision tree (Figure 1), processing marker states in the processMarkerSignals method. The decision process begins with a read operation that captures the current state of both markers, encoding them into a single value through binary manipulation: the right marker contributes the least significant bit (1), while the left marker sets the second bit (2), resulting in four possible states (0: no markers, 1: left only, 2: right only, 3: both markers).

Before entering the main decision logic, the system performs a critical optimization check: if the current state matches the last state (lastMarkerState == currentMarkerState), the method returns immediately, preventing unnecessary processing cycles. This early-return mechanism significantly reduces CPU load during steady-state operation when no markers are being detected.

Upon detecting a state change, the system enters its primary decision sequence. The root decision node examines the current state, with special emphasis on the ‘no markers’ state (0). When in state 0, the system traverses a carefully ordered sequence of pattern checks, each designed to identify specific track features through state history analysis. The sequence is deliberately ordered by priority: finish line detection takes precedence, followed by speed mode transitions, and finally intersection detection.

The finish line check looks for a specific pattern: a right marker only (state 2) followed by no markers, with the previous state also being no markers (lastMarkerState == 2 && previousMarkerState == 0). This three-state sequence definitively identifies the finish line pattern while rejecting spurious signals. When detected, handleFinishLine() executes, incrementing the lap counter and potentially initiating the stopping sequence.

If the finish line pattern isn’t matched, the system checks for speed mode transitions by looking for a left marker only (state 1) followed by a history of no markers (previousMarkerState == 0). This pattern triggers a complete mode transition through handleSpeedMode(), which orchestrates a comprehensive state reset. The speed mode handler not only toggles between precision and normal operation but also ensures a clean transition by resetting all motion-related states:

void handleSpeedMode() {

isPrecisionMode = !isPrecisionMode;

currentSpeed = isPrecisionMode ? SPEED_SLOW : BASE_FAST;

isTurning = false;

isExitingTurn = false;

boostCountdown = 0;

}The final check in the decision sequence examines whether any of the three previous states indicated both markers were detected (state 3). This more permissive check allows for intersection detection regardless of the exact sequence of marker readings, accommodating various approach angles and speeds. The handleIntersection() call logs the event but maintains current robot behaviour, as intersections don’t require specific responses in the current implementation.

After processing through the decision tree, the system executes its state history update, shifting each state one position in the history chain (oldMarkerState = previousMarkerState; previousMarkerState = lastMarkerState; lastMarkerState = currentMarkerState). This shift operation maintains the continuous state history required for pattern detection while minimizing memory usage through reuse of existing variables.

The process concludes with a check of the stopping sequence flags. When active, the stop sequence implements a two-phase deceleration: first reducing speed to SPEED_BRAKE if the slowdown timer hasn’t expired, then bringing the robot to a complete stop once the stop timer completes. This gradual stopping process ensures smooth deceleration while maintaining control throughout the stopping sequence.

6.2 Integration with Debug Layer

When operating in debug mode (DEBUG_LEVEL > 0), the system provides comprehensive data collection:

Event Logging:

- State transitions

- Speed mode changes

- Intersection detections

- Finish line crossings

Performance Monitoring:

- Speed adjustments

- Turn detection

- Boost activation

Stop Sequence Management:

if (isStopSequenceActive && !isRobotStopped) { if (!slowdownTimer.Expired() && currentSpeed > SPEED_BRAKE) { currentSpeed = SPEED_BRAKE; } else if (stopTimer.Expired()) { currentSpeed = 0; MotorDriver::setMotorsPower(0, 0); isRobotStopped = true; } }

6.3 Timing Considerations

The timing system implementation represents a critical aspect of RobotZero’s control architecture, orchestrating multiple time-sensitive operations through carefully calibrated intervals. At its core, the marker detection system operates on a fixed 2ms sampling interval, implemented through a time-difference check at the start of each reading cycle. This precise timing ensures consistent marker detection while preventing excessive sensor polling that could impact system performance. The sampling rate was determined through empirical testing to balance between reliable detection and system overhead.

When the robot initiates its stopping sequence, the system employs a two-phase timing approach. Initially, a 50ms slowdown period allows for controlled deceleration to SPEED_BRAKE, providing a smooth transition from full speed. After this initial brake phase, a longer STOP_DELAY interval guides the robot to a complete stop, preventing abrupt movements that could affect positioning accuracy. These timing values work in concert with the speed adjustment system, which uses `ACCELERATION_STEP` and `BRAKE_STEP` to control velocity changes. The step values create a gradual acceleration and deceleration profile, protecting the motors while maintaining precise control over the robot’s movement.

Post-curve speed management introduces another timing element through the boost system. When exiting a curve, the boostCountdown timer activates for a configurable duration (`BOOST_DURATION`), during which the robot can temporarily exceed its normal speed limits. This boost phase is carefully timed to maximize straight-line performance while ensuring the robot maintains stability as it transitions from curved to straight sections. The timing parameters across these systems are interdependent; for example, the marker reading interval must be fast enough to detect course features even at maximum boost speed, while the acceleration steps must be calibrated to work effectively within the boost duration window.

6.4 ProfileManager Implementation

The ProfileManager serves as RobotZero’s configuration system for different operating modes, providing two distinct profiles: one optimized for analysis and another for high-speed performance. This implementation is entirely conditional, only compiled when DEBUG_LEVEL is greater than 0, ensuring zero overhead during normal operation.

class ProfileManager {

public:

// Initialize profile manager

static void initialize(DebugMode mode);

// Get current debug mode

static DebugMode getCurrentMode();

// Get speed value based on original speed constant

static uint8_t getSpeedValue(uint8_t defaultSpeed);

// Get PID parameters

static float getKP(float defaultValue);

static float getKD(float defaultValue);

static float getFilterCoefficient(float defaultValue);

// Get acceleration parameters

static uint8_t getAccelerationStep();

static uint8_t getBrakeStep();

static uint8_t getTurnSpeed();

static uint8_t getTurnThreshold();

static uint8_t getStraightThreshold();

static uint8_t getBoostDuration();

static uint8_t getBoostIncrement();

private:

static DebugMode currentMode;

static const SpeedProfile* activeProfile;

static const SpeedProfile ANALYSIS_PROFILE;

static const SpeedProfile SPEED_PROFILE;

static void setActiveProfile(DebugMode mode);

static uint8_t validateSpeed(uint8_t speed);

};The system is built around two predefined profiles, each optimized for specific purposes:

const SpeedProfile ProfileManager::ANALYSIS_PROFILE = {

// Speed settings - Conservative for analysis

.speedStop = 0,

.speedStartup = 60, // Slower startup

.speedTurn = 80, // Careful turns

.speedBrake = 90, // Gentle braking

.speedCruise = 100, // Moderate cruising

.speedSlow = 120, // Moderate slow speed

.speedFast = 140, // Moderate fast speed

.speedBoost = 160, // Moderate boost

.speedMax = 180, // Limited top speed

// Control parameters - Smooth operation

.accelerationStep = 15, // Gentle acceleration

.brakeStep = 40, // Moderate braking

.turnSpeed = 80, // Conservative turns

.turnThreshold = 50, // Earlier turn detection

.straightThreshold = 25, // Stricter straight detection

.boostDuration = 8, // Short boost

.boostIncrement = 15, // Gentle boost

// PID parameters - Stable control

.kProportional = 4.0f,

.kDerivative = 500.0f,

.filterCoefficient = 0.5f

};

const SpeedProfile ProfileManager::SPEED_PROFILE = {

// Speed settings - Aggressive for performance

.speedStop = 0,

.speedStartup = 100, // Quick startup

.speedTurn = 120, // Fast turns

.speedBrake = 140, // Strong braking

.speedCruise = 160, // Fast cruising

.speedSlow = 180, // Fast slow mode

.speedFast = 200, // High speed

.speedBoost = 220, // Strong boost

.speedMax = 255, // Maximum speed

// Control parameters - Performance focused

.accelerationStep = 35, // Quick acceleration

.brakeStep = 70, // Strong braking

.turnSpeed = 140, // Fast turns

.turnThreshold = 40, // Later turn detection

.straightThreshold = 15, // Quicker straight detection

.boostDuration = 12, // Longer boost

.boostIncrement = 25, // Strong boost

// PID parameters - Aggressive control

.kProportional = 6.0f,

.kDerivative = 700.0f,

.filterCoefficient = 0.7f

};Implementation Note:

TODO: These variables should be transferred to macros or constexpr’s in the configuration layer, maintaining the system’s design principles of compile-time optimization and centralized configuration.

The translation between default values and profile-specific values is handled through the getSpeedValue method:

uint8_t ProfileManager::getSpeedValue(uint8_t defaultSpeed) {

if (activeProfile == nullptr) {

return defaultSpeed;

}

// Map original speed constants to profile values

if (defaultSpeed == SPEED_STOP) return activeProfile->speedStop;

if (defaultSpeed == SPEED_STARTUP) return activeProfile->speedStartup;

if (defaultSpeed == SPEED_TURN) return activeProfile->speedTurn;

if (defaultSpeed == SPEED_BRAKE) return activeProfile->speedBrake;

if (defaultSpeed == SPEED_CRUISE) return activeProfile->speedCruise;

if (defaultSpeed == SPEED_SLOW) return activeProfile->speedSlow;

if (defaultSpeed == SPEED_FAST) return activeProfile->speedFast;

if (defaultSpeed == SPEED_BOOST) return activeProfile->speedBoost;

if (defaultSpeed == SPEED_MAX) return activeProfile->speedMax;

return validateSpeed(defaultSpeed);

}The Analysis Profile is designed for development and testing, with conservative speeds and gentle transitions. It prioritizes stability and predictability over raw speed, making it ideal for collecting performance data and tuning control parameters. All speed values are reduced, acceleration is gentler, and the PID parameters are tuned for stability.

The Speed Profile, in contrast, is optimized for maximum performance. It uses aggressive speed settings, quick transitions, and more responsive control parameters. The PID constants are increased for faster response, and the thresholds are adjusted to maintain control at higher speeds. These profiles have not yet been tested in competition conditions.

The ProfileManager ensures smooth operation by validating all speed values and providing fallback behaviour when no profile is active. When DEBUG_LEVEL is 0, the entire ProfileManager code is excluded from compilation, maintaining the efficiency of the production code.